News

The Future of Geomembranes

Authors

J. Scheirs

1. Director, ExcelPlas, Melbourne, VIC, Email: john@excelplas.com.au

Introduction

Time travelling to 2050 what will the geomembrane technology look like?

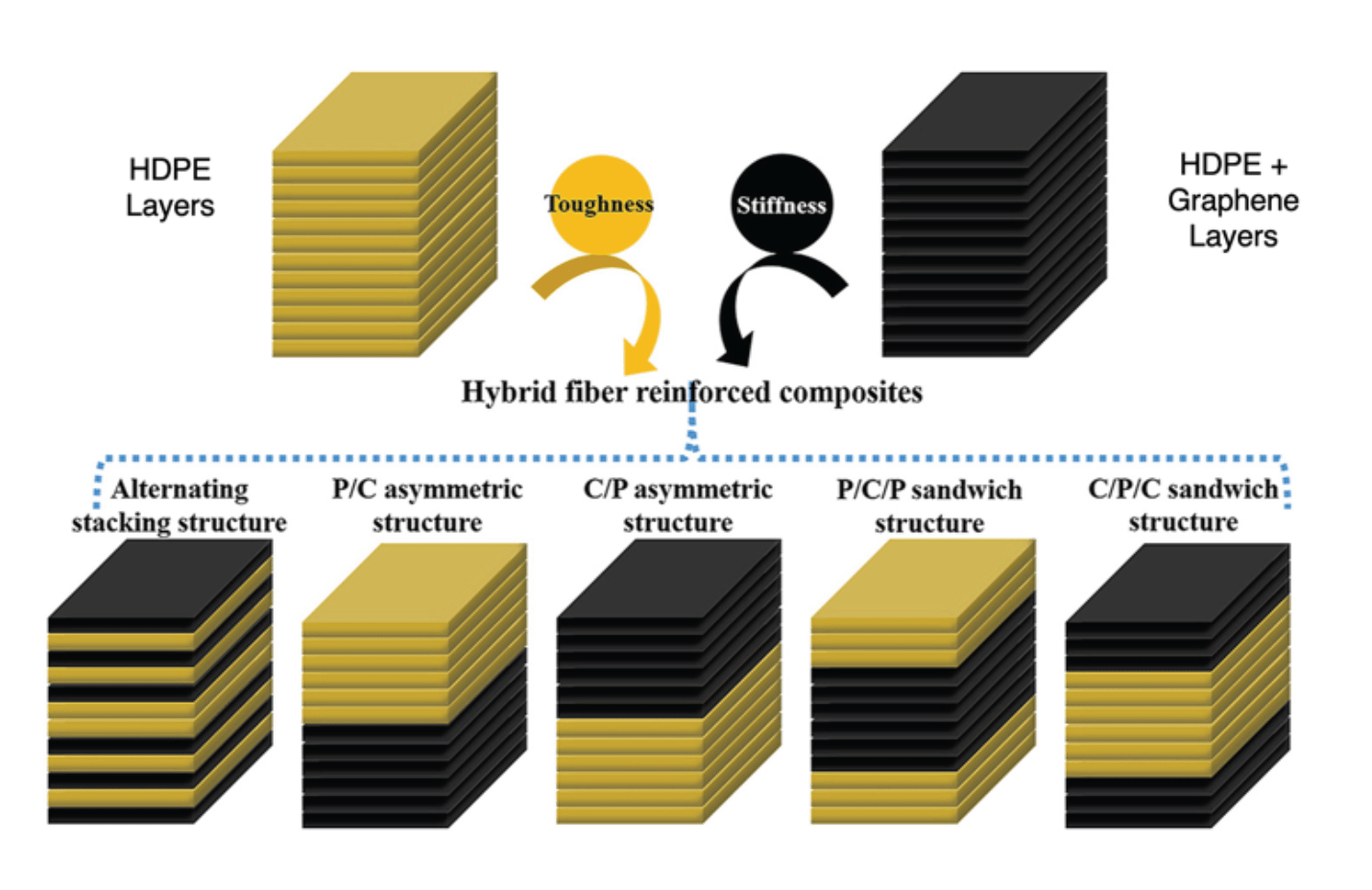

The future of geomembranes lies in the creation of multilayer geomembranes consisting of stacks of different polymers which can be arranged in many combinations to achieve specific end-use properties.

Given the numerous combinations of the ways the layers can be arranged a host of performance properties can be achieved. New and novel geomembranes can be produced by simply altering the order of the layers in the stack.

New Technology

New coextrusion technology with multilayer dies can now produce 7, 9 and 11 layers. Just as the cards in a pack of playing cards can be arranged in a host of different combination so to can the layers in a geomembrane.

These engineered geomembranes (EG) can have significantly enhanced performance properties, allowing sheets to be made thinner, stronger, and with better welding and seaming properties.

The composition and arrangement of the individual layers allows the geomembrane properties to be ‘tuned’ to give unique properties. For example, by using alternating layers of non-conductive and conductive HDPE the geomembrane can work like a capacitor to hold charge (essentially a battery). Or by alternating layers of metallocene PE with a PE plastomer highly flexible geomembranes can be made with outstanding multiaxial burst properties for gas methane gas storage.

New advancements in multilayer technology, including its capability to produce hundreds of layers in a single film by a melt coextrusion process. This new technology known as microlayer coextrusion processing technology can produce stacks of microlayers with a host of potential applications, thus helping geosynthetic research scientists and engineers develop products which not only fulfill their primary function, but can also be manufactured reliably, safely, and economically.

Potential future trends in multilayer coextrusion technology will enable geosynthetic engineers and scientists to stay ahead of the curve in this rapidly advancing area.

SO Many Possibilities

Each geomembrane sheet structure layer may be chosen to provide a specific functionality or property. A multilayer polyethylene film structure may be designed to achieve targeted performance requirements for specific end-use applications in a cost-effective, value-added and recyclable manner.

Some possible desirable properties of a geomembrane structure may include barrier properties (B), chemical resistance (C), electrical properties (E), mechanical properties (M), recyclability (R), stability (S) and weldability (W), each of which may be tailored by the nature and order of the polymer layers in the geomembrane sheet structure. For example, just the following 7 layers namely B, C, E, M, R, S, W can be arranged in 5040 different combinations.

This allows customization of mechanical properties such as elongation, puncture, tear, burst and barrier properties such as impermeability to methane, PFAS and radon.

A recent patent discloses that a geomembrane made from 9 alternating layers of HDPE (polymer A) and LLDPE (polymer B) has exception puncture strength when the two polymers are arranged in the following structure: A/B/A/B/A/B/A/B/A.

Self-Reinforced Geomembranes

Alternating layers of hard and soft polymers such as HDPE and LLDPE will give a reinforcing affect similar to the way the carbon fibre laminates are produced. A self-reinforced polymer composite is made of a single polymeric material, which serves as both the matrix and the reinforcement. For example EverLiner® is composed of PTFE tape reinforcement and PTFE plies making it a 100% PTFE material.

Self-reinforced polymer composites, also known as single-polymer composites, appear to be composed of the same constituent in which a polymeric matrix is reinforced with fillers (which may be fibres or particles) of the same polymer. Self-reinforced HDPE geomembrane for example have incredibly high tear resistance while maintaining good flexibility.

Due to its relative homogeneity, this single component system allows one to achieve perfect interfaces between matrix and reinforcement (which is not possible in heterogeneous composites such as scrim-reinforced geomembranes) and more possibilities for producing recyclable products than composites made of two or three distinct components.

Furthermore, recycling thermoplastics is easier than recycling thermosets, which may contribute to the concept of a material circular economy. Self-reinforced composite geomembrane materials also display exceptionally good mechanical property profiles.

Conclusions

The future of geomembranes lies in the development of multilayer geomembranes consisting of stacks of different polymers. By arranging the layers in specific combinations, a host of performance properties can be achieved, leading to the creation of new and novel geomembranes.

The new coextrusion technology with multilayer dies has allowed for the production of custom geomembranes with specific performance properties, resulting in longer service life and reduced maintenance costs. The possibilities for creating new and innovative geomembranes are endless, and this technology is poised to revolutionize the field of geotechnical engineering.

Each layer has a specific function throughout the layout such as inherent toughness or flexibility. The use of multilayer extrusion casting technology can produce multilayer sheets with specific functionality.