Rubber and Elastomer Testing

ExcelPlas provides testing of rubbers, sealants, elastomers, thermoplastic elastomers (TPE-s, TPE-o, TPV, TPU).

As the leaders in Material Characterization, QA/AC, and Failure Analysis, we have the ability to produce accurate and fast results using state-of-the-art testing equipment.

The services offered by our NATA-accredited laboratories in Melbourne, Australia are independent and confidential.

Chemical Characterization |

Mechanical Characterization |

|---|---|

| Oxygen Index (ASTM D2863) | Tensile (ASTM D412) |

| Carbon Black Content (ASTM D 4218) | Tear of Sheet (ASTM D624C) |

| Pyrolysis FTIR (ASTM D3677) | |

| VOC (ASTM D3530) | |

| Degree of Crosslinking (ISO 10147) | |

| Gel Content | |

| Degree of Swelling | |

| EDAX Analysis |

Physical Characterization |

Thermal Characterization |

|---|---|

| Hardness: Shore A, Shore D (ASTM D2240) | DSC – Tg (ASTM D5028, ASTM D7426) |

| Abrasion (ASTM D4060, AS 1683.21) | DSC – Melting/Crystallization (ASTM D3418) |

| Density (ASTM D792) | DSC – OIT (ASTM D3012) |

| TGA (ASTM D6370) | |

| Thermal Expansion | |

| Rheology |

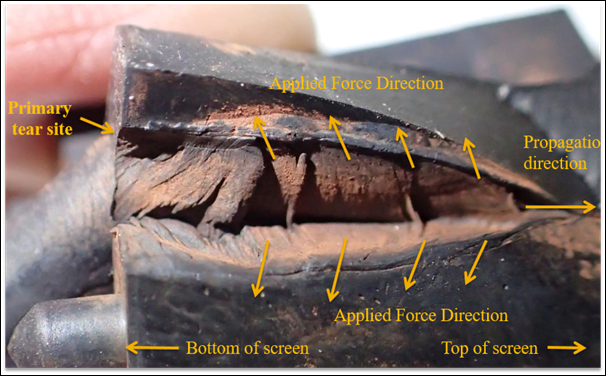

Failure Analysis

ExcelPlas is able to conduct failure analysis of rubbers and elastomers (O-rings, belts, liners, sealants, etc.) using techniques such as Microscopic Analysis.