News

How the Baltimore Bridge Collapse Could Affect Geosynthetic Supply Times and Costs

Authors

By GNA Editor | 2nd April 2024

The recent collapse of Baltimore’s Francis Scott Key Bridge, caused by a cargo ship collision, has sent shockwaves through the maritime industry, raising concerns about the safety of port infrastructure and the potential repercussions for various sectors, including the geosynthetic industry. As approximately 85 percent of geosynthetics are transported via ocean-going vessels, any disruption or incident in the shipping industry can have far-reaching effects on supply chains and associated industries.

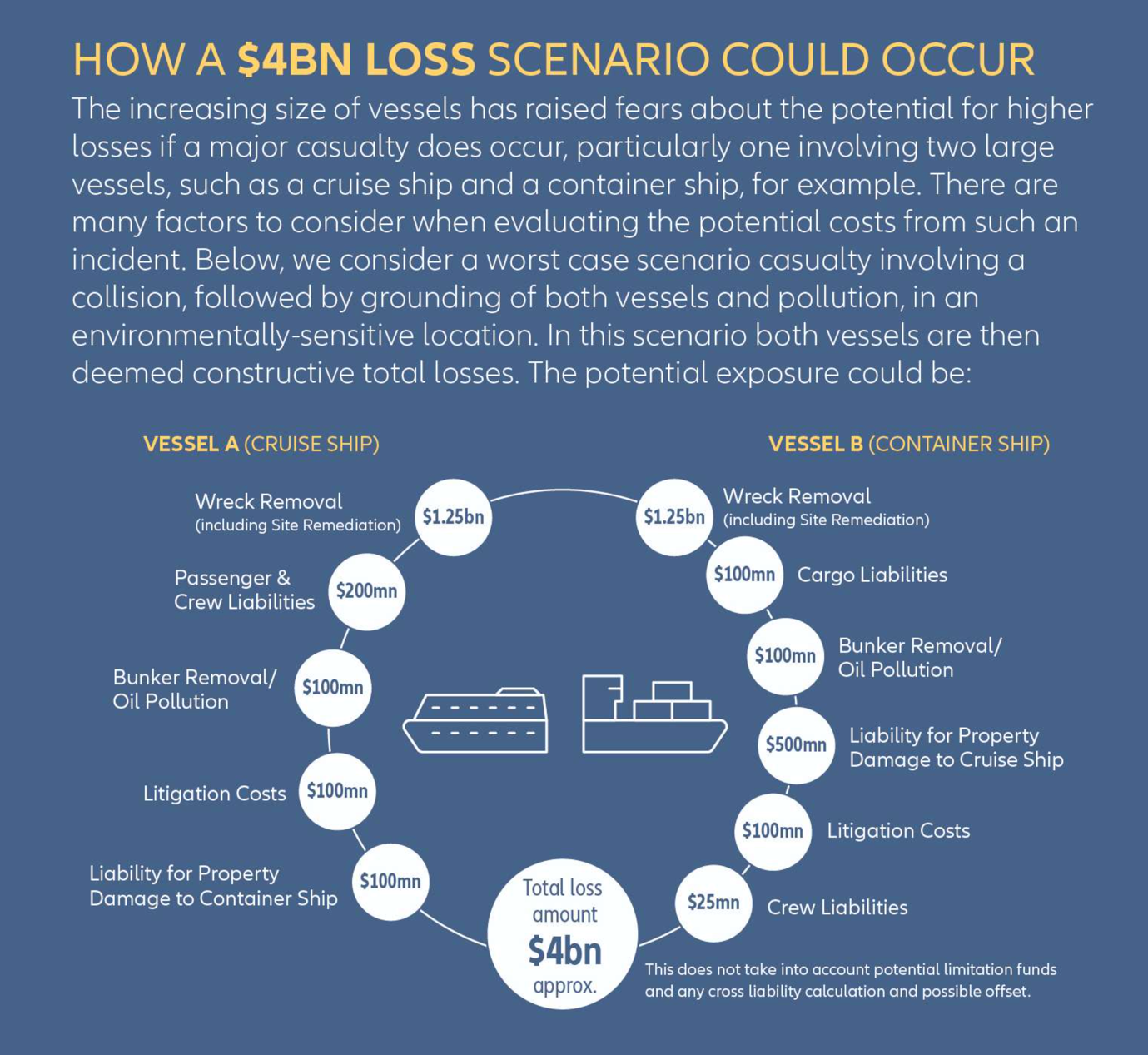

The incident highlights the growing trend towards larger and more efficient vessels in the shipping industry. While advancements in vessel technology have led to increased cost-effectiveness and efficiency, allowing for the transportation of larger cargo volumes at lower costs, they have also raised concerns about the concentration of risk. The shift towards larger container ships, capable of carrying tens of thousands of shipping containers, means that more cargo is concentrated on fewer vessels. This concentration poses significant risks in terms of potential accidents and incidents.

According to Niels Rasmussen, chief shipping analyst at the Baltic and International Maritime Council (BIMCO), the average size of container ships has doubled since 2006, with ships exceeding 12,000 TEU (Twenty-foot Equivalent Unit) accounting for a significant portion of the fleet’s capacity. This trend is expected to continue, with larger ships dominating the order book. The concentration of cargo on these massive vessels raises concerns about the potential consequences of accidents, such as collisions with port infrastructure.

The Allianz Commercial Safety and Shipping Review has reported nearly 2,000 incidents of ships colliding with port infrastructure over the past decade, with container ships being involved in approximately 200 of these incidents. While most of these incidents involved piers and harbor walls, the potential for accidents involving larger vessels carrying massive cargo volumes cannot be overlooked.

The implications of incidents such as the Baltimore bridge collapse extend beyond immediate safety concerns. They can also impact supply chains and logistics, including the geosynthetic industry. Geosynthetics, including liners used in various applications such as landfills, pond liners, and containment systems, are crucial components in infrastructure projects, including those related to ports and harbors.

The disruption caused by accidents in port infrastructure could lead to delays in shipments and increased costs for various raw polymer materials, including resins for geosynthetics. Supply chain disruptions may result in shortages of critical materials, leading to delays in construction projects and increased project costs. Additionally, the need for repairs and upgrades to damaged infrastructure may increase demand for geosynthetic products, further impacting supply times and costs.

In conclusion, the recent Baltimore bridge collapse serves as a reminder of the risks associated with the increasing size and concentration of cargo on container ships. As incidents involving port infrastructure continue to occur, it is essential for stakeholders in the maritime and related industries to address safety concerns and implement measures to mitigate risks. Additionally, businesses reliant on maritime transport, including the geosynthetic industry, must be prepared to adapt to potential disruptions in supply chains and assess the impact on costs and project timelines.